BETAFLEX PRO1 & BETAFLEX PRO2 FLEXO PLATE & IMAGE ANALYZER - OPTIONS & ACCESSORIES

by Beta Screen CorporationBETAFLEX PRO2 FLEXO PLATE & IMAGE ANALYZER - OPTIONS & ACCESSORIES

YouTube Video Link & Below

BetaFlex Pro2 Home Page

ZZZZ

BetaFlex Pro2 Options & Accessories pdf

ghghf

Today's BetaFlex Pro2 Flexo Plate & Image Analyzers have various options to streamline your Flexo Image and Print Analysis for simplified integration and data collection in your production workflow.

-

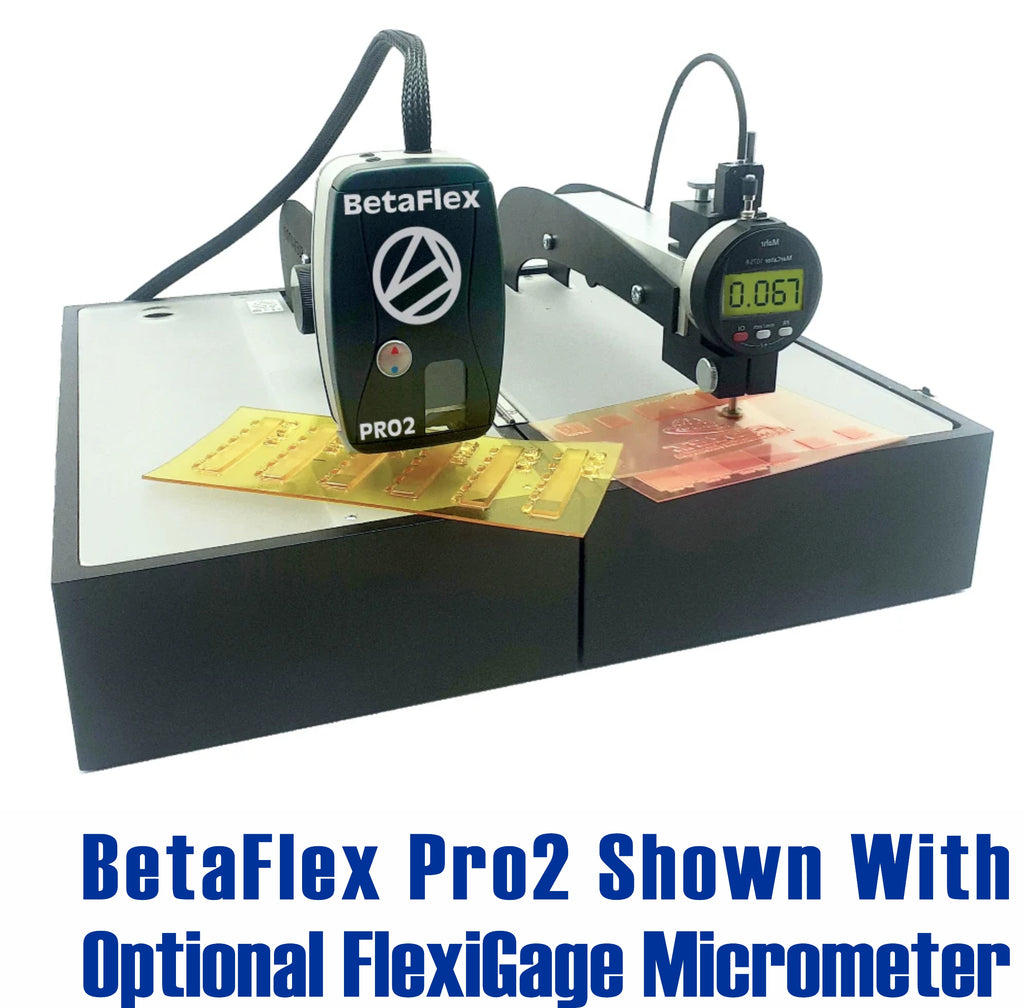

FlexiGage Micrometer - Measure Gauge & Relief (BetaFlex Pro1)

-

FlexiGage Micrometer - Measure Gauge & Relief (BetaFlex Pro2)

-

BetaFlex Pro1 Version 6 Software Upgrade / Windows 11 Compatibility (Upgrade your BetaFlex Pro(1) to the current software for greater functionality and Windows 11 compatibility!

The BetaFlex Pro2 Flexo Plate & Image Analyzers is Beta's 3rd generation Flexo image analyzer in a history that spans more than 30+ years starting with the introduction of the first image based analyzer for dot area, dot percentage analysis.

ZZZZ

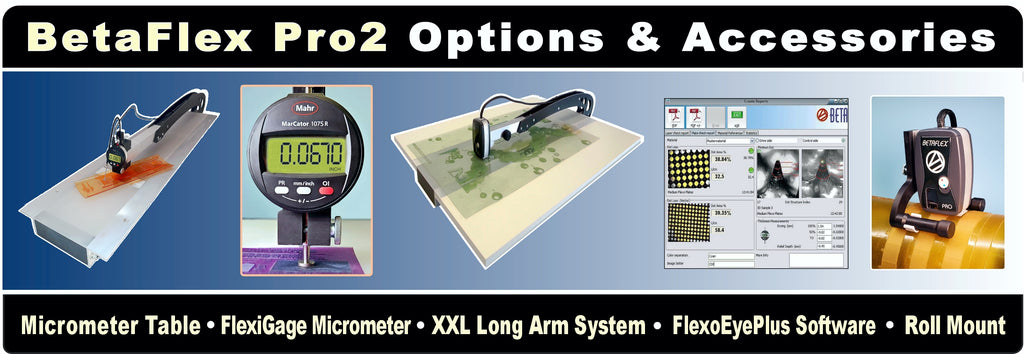

OPTIONS & ACCESSORIES

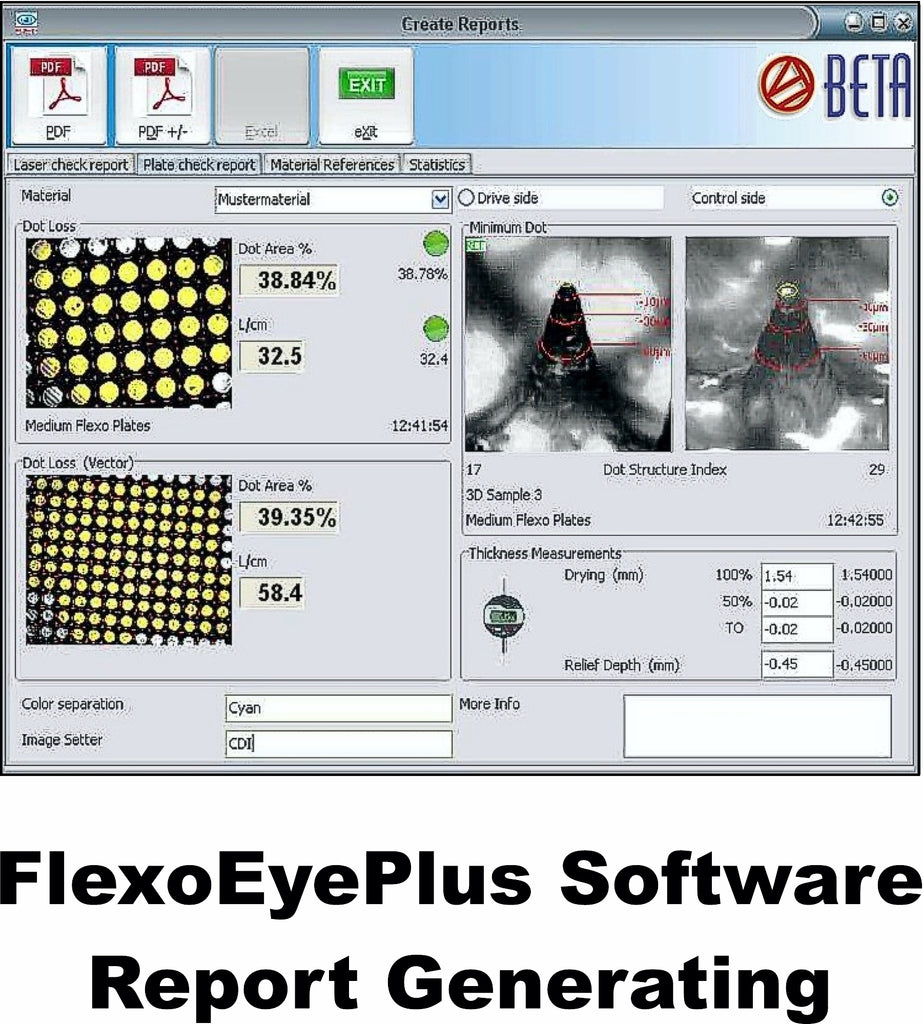

FlexoEyePlus Software - Streamlined Automatic Data Collector & Report Generator

FlexoEyePlus simplifies data collection for high-end production. Tightly integrated into the standard software application, it introduces convenient PASS/FAIL icons to evaluate minimum and midtone dot, stain density, cutback curve, plate relief, and more while displaying the data on a concise display and plotting the day's production on a convenient graph.

FlexoEyePlus works seamlessly with the optional FlexiGage Digital Micrometer and is a required part of the software suite. Plate gauging data is automatically written into the same report as 2D halftone data and 3D dot structure data.The reporting suite consists of four highly detailed and illustrated reports;

-

Laser Check report – verifies Laser Power, Focus, Linearity, and Minimum Dot formation

-

Plate Check report – ties Plate Material, Job ID, Min Dot, Process and Workflow Curves together

-

Material Reference – allows creation of a Plate material file used as input to Laser and Plate reports

-

Statistics – creates plots of Laser and Plate report data across user-selected materials and dates

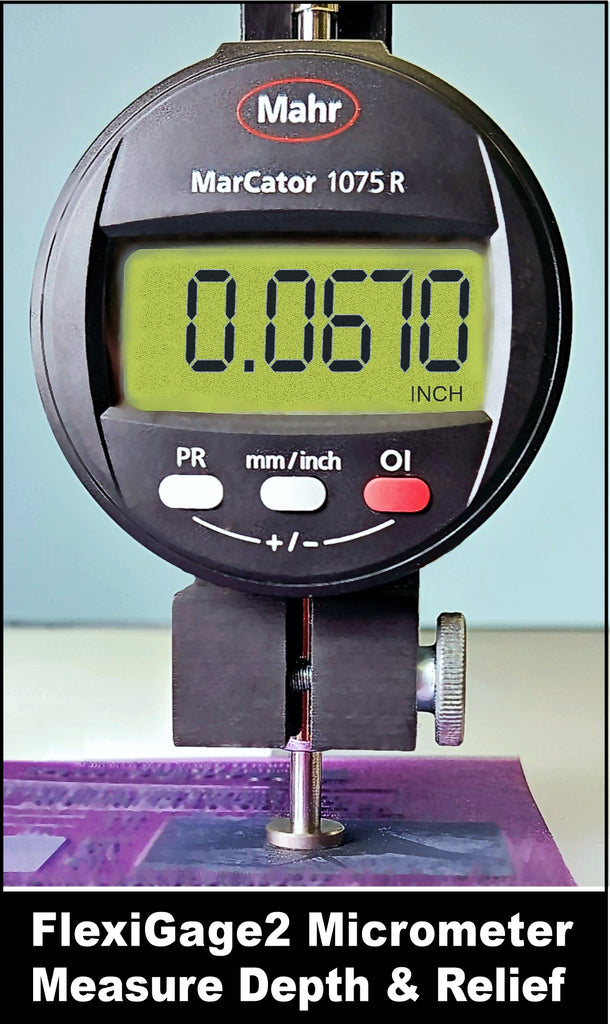

FlexiGage Plate Micrometer - Measures and Document Gauge and Relief

-

FlexiGage2 Micrometer & Software Digital Plate Micrometer & FlexoEyePlus Software seamlessly integrates measurements of gauge and relief into professional reports for ISO and customer compliance.

-

FlexiGage for Sleeve Adaptor used with Betaflex Pro Sleeve Adaptor for Flexo Sleeves.

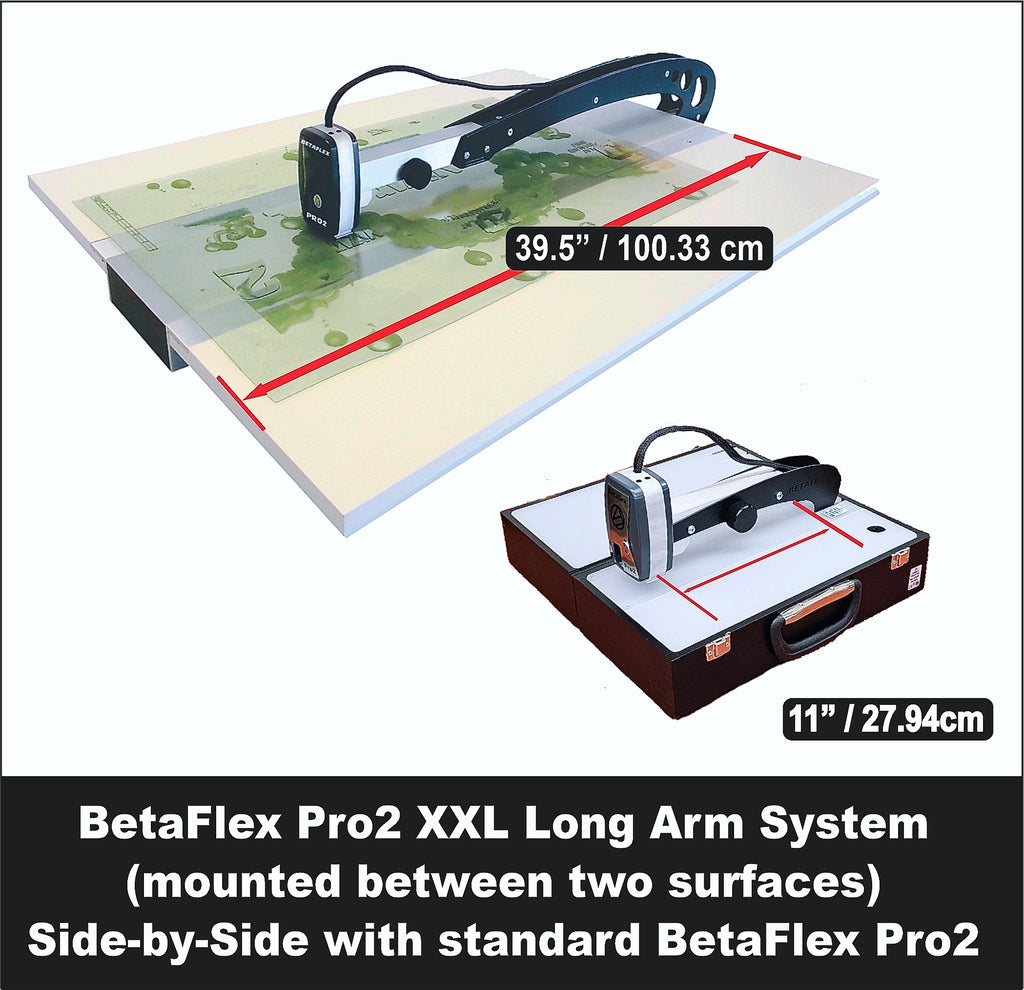

Betaflex Pro2 XXL Long Arm System or XXL Adaptor

-

Betaflex Pro XXL Long Arm System or XXL Adaptor (for use with your existing BetaFlex Pro System) mounts the Betaflex Pro Sensor/Meaureing Head or FlexiGage Micrometer 30 inches (76.2 cm) from the edge of the plate for plates of 60 inches (152.4 cm) or larger. Required for transmission plate and mask analysis, the XXL greatly simplifies 3D, print, and thickness/relief analysis of large samples.

-

Betaflex Pro XXL Long Arm System includes Betaflex Pro Sensor / Measuring Head to the above mentioned XXL Long Arm adaptor.

Roll Mount Adaptor

Roll Mount Adaptor for Betaflex Pro Sensor to inspect plate wear on press & web print samples

BetaFlex Micrometer Table - Easy-to-Fit & Affordable. Installed in minutes.

Measure & Document Plate Depth & Relief - Save Time, Money & Space

The Economical, Easy-Fit, Retro-Fit Micrometer Table With High Resolution Micrometer & Optional Database

Measure Plates as Large as 60” / 152.4 cm

NO NEED TO PURCHASE OR BUILD A LARGE DEDICATED MICROMETER TABLE AND ROOM

Betaflex Pro Sleeve Adaptor System

BETAFLEX PRO2 PLATE & IMAGE ANALYZER

TECHNOLOGY FOR TODAY'S FLEXO

The BetaFlex Pro2 operates at the highest resolution to provide the most accurate and consistent measurements for your flexo control process and analysis.

HD Flexo, stochastic screening, high resolution dot area (%), print and film measurement, and all the most sophisticated prepress techniques can be measured and controlled with ease and accuracy in one device that comes complete with all necessary hardware, software, and technical support at no additional cost to user. Also included are all firmware / software updates.

Revolutionary 3D imaging and DOT STRUCTURE Mode add topographical visualization to the conventional dot area halftone measurements. Dot height, diameter, slope and more are visualized and automatically measured at 22,000 PPI. Surface enhancement techniques are easily seen and quantified.

The new high resolution system is portable and easy to use. Operating in TRANSMISSION mode at 14,000 PPI, it quickly and accurately measures all types of transparent flexo plates, digital ablation masks, and halftone films. The new Mask Stain Density function eliminates the need to carry an old fashioned film densitometer to verify laser energy, focus, and beam adjustments.

In PRINT mode, "Color Separation Analysis" imaging of color prints on film and paper provides measurements of Dot Area, Screen Ruling, Edge Factor and more. Excellent for work where there is no room for printed targets like cosmetic and pharmaceutical work. Data and images are easily captured and printed with the integral report generator and statistical analyzer. Offset plates can also be measured.

The new automatic 4 point calibration system eliminates the need to make multiple manual measurements. The Calibration Target and software system maintains a database of the instrument status to satisfy the most stringent ISO registration requirements. All of this is combined with the high precision, ease of use, and Beta product support that has made Betaflex the standard for Flexo Quality Control.

-

Measure flexo plates, films, and digital masks in conventional 2D mode (.5% at 250 lpi and better)

-

Dot Structure Analysis in 3D mode reveals dot height, slope, and more

-

Print mode measures true mechanical dot area on offset plates and prints

-

Automatic 4 point calibration system with ISO-compliant target

-

Mask Stain density function for laser ablation setup

-

Image Overlay and Comparison function to visialize and measure dot changes

Download Brochure

Download Betaflex Pro Brochure in Spanish

Download PDF of the Betaflex Pro Power Point

Download BetaFlex Pro Technical Documents

Contact your local dealer or Beta Industries for pricing, delivery, and training information. The Betaflex PRO and Betaflex Xpress flexo analyzers are also sold under the Flex3 PRO and Flexcube PRO and Flex3 and Flexcube brand in Europe an Asia. This is one of several new Beta products that replace the Betaflex 334, Betaflex 335 PQF, and Vipflex systems.

Contact us for the BetaFlex Pro2 demonstration software

Includes a FREE BetaColor Viewer 3, a $515 value. The BetaColor Viewer 3 is the industry standard for critical CMYK color evaluation and is recognized by all segments of the industry with more than 20,000 units sold. View colors enhanced with LED's in high contrast. Yellow and other colors appear virtually black.

About Beta's 10-Day Free Trial for this product, Click Here.

Betaflex Pro Testimonials

The Betaflex Pro helps my team produce better work through live images and measurement data.

Its easy to use/learn; after a few uses operators have it down. As a manager this device has helped us 'cut through the bias' during plate & print troubleshooting and kept the focus on the problem/solution. You cannot put a price on that; after a few print/plate troubleshooting sessions it paid for itself.

I have only contacted the Betaflex support team once or twice and they had an answer for me in less than 24hrs.

I would recommend the Beta Pro to anyone producing flexo or letterpress plates as well as film negatives. It also works well as a print analyzer.

When it comes to plates seeing is believing and measurement is king; BetaFlex Pro does both. We are very satisfied with the product.

Steven Rice

Dart Container

------------------------------------------------------------------------------

As a QA tool it does help us “produce better work” by allowing our team to peer into our platemaking process to ensure that the final product is within the established ranges for each attribute that we measure.

The customized settings for plate specific tolerances have been quite helpful. The foot pedal for the controls also means more of a hands free operation that some operators find helpful.

As plate technologies have evolved and process controls have become tighter, it has become very important to have a dependable measurement tool that allows you to measure and understand what is imaged on the mask and what is formed on the finished plate.

We have established a good relationship with Beta. They have been willing to understand what we were trying to accomplish and have done a good job supporting our efforts via email, phone calls, and screen sharing support.

If someone was looking for a tool to help them better understand their platemaking process and is willing to invest the time to setup the proper procedures, then we would certainly recommend the BetaFlex Pro.

Tyler S. Mills

Special Projects Manager | Cyber Graphics

------------------------------------------------------------------------------

We have been using the BetaFlex Pro for approximately 3 years.

We find it very helpful to assess the quality of our printed product and to refer to it to analyze and determine if adjustments are necessary at press side, or in pre-press.

We also use it to review HD dots on our plates. There have been numerous occasions where the Betaflex PRO has saved us money at press side.

I enjoy using the BetaFlex Pro and have found it to be a very valuable tool.

Dina Russo

Yerecic Label

Pre-Press Manager

------------------------------------------------------------------------------

I have discovered a new solution for reading white ink mottle on PRINTED FOIL!

This stunned the printer in 15 minutes as they have been searching for a way to do this for a long time. Ironically while I was there they were conducting white ink trials on foil and using only using visual pass/fail methods.

I did this on my computer with my BetaFlex Pro in front of them. I could not have done any of this without the BetaFlex Pro.

David A Recchia | Application Development Sr.

Printing Process Specialist

Macdermid Printing

Share This