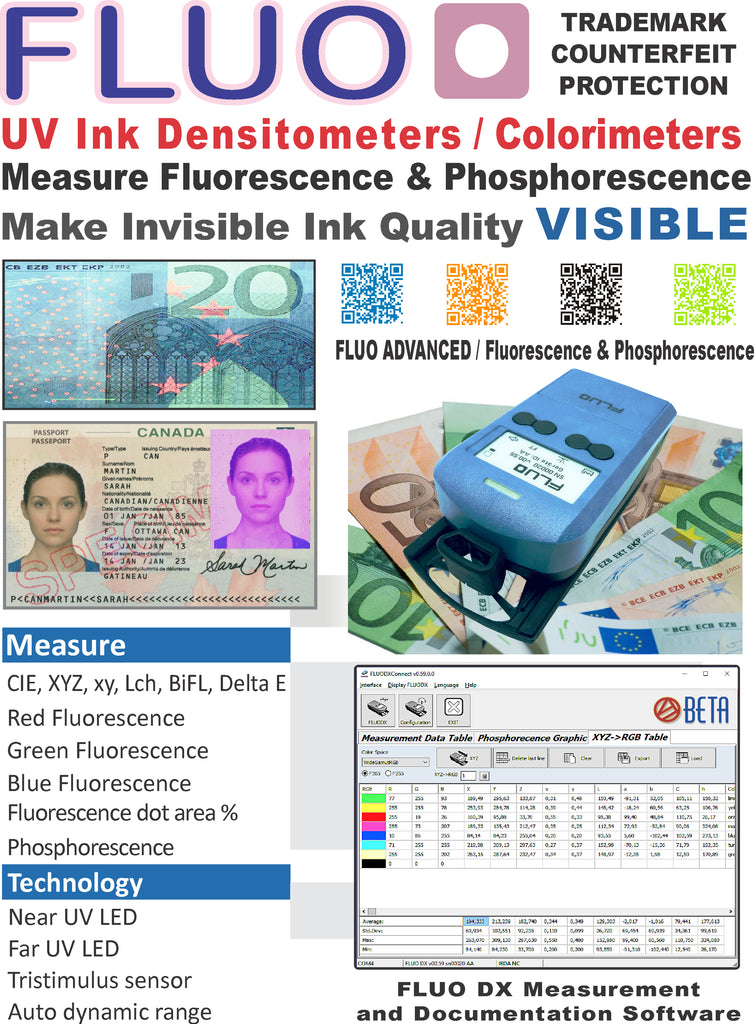

BETA FLUO - Invisible UV Ink Densitometer / Colorimeter Measure UV Ink Fluorescent and Phosphorescent UV Ink Density & Other Print Production Parameters for Better Process Control

Bring the advantages of process control and productivity to your invisible UV ink printing and marking activities.

the Beta Fluo ADVANCED, fitted with a 365nm and 256nm source and the Beta Fluo BASIC, equipped with a 365nm UV source, bring the benefits of rugged, easy-to-use instruments to the production floor, QC lab, and on-site verification.

FLUO BROCHURE

FLUO BROCHURE (ESPANOL)

Applications

- Banknote printing companies

- Security Ink manufacturers

- Security Label printers

- Packaging printers in general who want to apply fluorescent or phosphorescent security elements on carton boxes, flexible plastic film packaging

- Transparent – fluorescent plastic Film

- Security phosphorescent Labels (security at work etc.)

- Paper mills (optical brightener control)

Two control modes are available with the FLUO;

- INTENSITY Control measures the overall intensity of the fluorescence & phosphorescence

- COLOR Control measures the visual color effect of fluorescence & phosphorescence

(1) Controlling the intensity of the fluorescent or phosphorescence signal is similar to controlling the density of a conventional color on press.

(2) Controlling the color of the fluorescence and phosphorescence is comparable to gray balance control with conventional inks. Overprints or specially formulated multi-pigment inks can be used to create special color effects.

When an OK sample is present, and printing, ink mixing, or inspection personnel need to verify starting conditions or on-going production, the FLUO Basic offers a large, clear display of visible fluorescent emission intensity relative to the standard. Errors in ink film thickness, ink jet clogging, or ink load formulation are detected before time and material are wasted.

Fluorescent color analysis is also presented as RGB channel signal strength, providing a simple comparison of the color of the production sample to the OK sheet.

Measurements can be saved via the USB connection to the PC for further analysis and reporting.

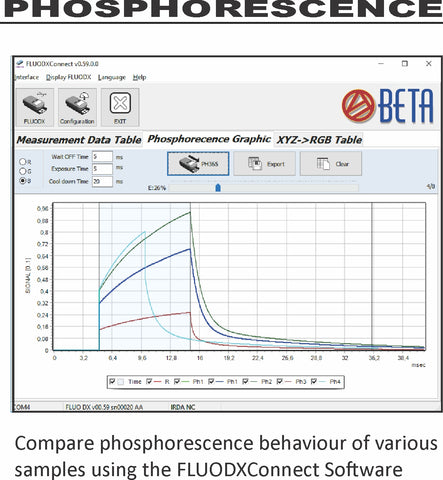

The Beta Fluo ADVANCED greatly extends the measurement, analysis, and display capabilities of the FLUO system. Dual UV LED sources and dynamic emission measurement characterize the relative and absolute intensity and colorimetry of fluorescent materials. Phosphorescent charging and discharge characteristics are measured with millisecond precision, and dual-color materials are analyzed under 256nm and 365nm illumination.

The high resolution paper-white display presents operator prompts, measurement data, statistical analysis, and graphical analysis. Extensive internal storage and included Windows software simplify capture and upload of reference materials, eliminating the need for physical samples of approved production.

The wireless IRDA data transfer complements the USB upload and download capability, while the UV illuminated target finder assists the operator in locating the targets.

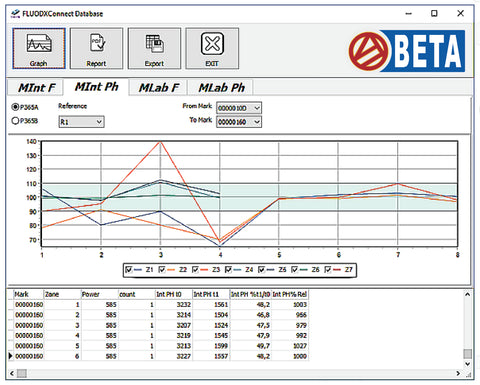

FLUODXConnect Windows database software (FREE) greatly increases the convenience and utility of the Beta FLUO ADVANCED on the production floor, in the QC department, and in the research lab and is included with the Fluo Advanced with purchase.

USB connectivity allows data upload and download as well as device configuration. The IRDA wireless datalink simplifies upload of measurement data to the PC. A unique feature of the system is the device screen capture, allowing the FLUODX screen to be included in training documents or displayed in real-time to a training audience.

FLUO DXConnect PRO Software FLUODX Connect PRO software supports any company new to anti-counterfeiting applications in packaging for you to document your first anti-counterfeit protected folded box, flexible packaging or label with a few mouse clicks using the “Secure Icon Creator”.

It works for Offset, Flexo, Gravure, and digital printing.

#InvisibleInkDensitometer #InvisibleUVInkDensitometer #UVInkDensitometer #SecurityInkUVInkDensitometer #UVInkMeasuring, #FluoUVInkMeasuring, #PeretFluoUltraVioletInkMeasuringDensitometer

BETA FLUO ADVANCED: Invisible UV Fluorescent and Phosphorescent Densitometer / Colorimeter: Measure UV Ink Density & Other Print Production Parameters for Better Process Control

FLUO DXCONNECT DATABASE SOFTWARE FOR FLUO ADVANCED COLORIMETER