FLUO DXConnect PRO Software for use With the FLUO ADVANCED UV Fluorescent and Phosphorescent Measuring Colorimeter

by Beta Screen Corporation

SEE BETA FLUO UV INK MEASURING COLORIMETERS PAGE

FLUO BROCHURE

1. FLUODX Connect PRO software allows any company to create secure, covert graphics to protect their packaged products. The SECURE ICON CREATOR takes the designer’s artwork and transforms it into an anti-counterfeiting graphic to be printed with invisible UV fluorescent inks. Use your existing flexo, offset, gravure or screen process equipment to apply an authenticated graphic to protect your label, folding carton, or flexible packaging

It works for Offset, Flexo, Gravure, and digital printing.

Anybody can do it, nobody can copy it.

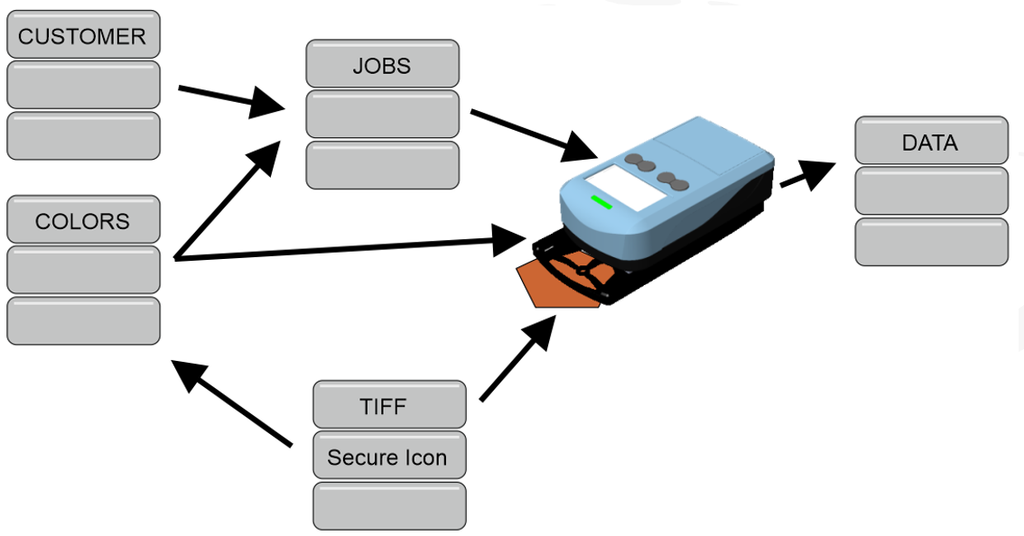

2. FLUODX Connect PRO software supplements the set of references stored in the FLUO ADVANCED device from 4 references to maximum of 12 per measurement mode. In order to still know, which reference stands for what, a unique name with a maximum of 5 characters can be assigned to a reference which will be displayed in place of R1..R4. The reference colors can be uploaded and downloaded and saved in a database on the PC. The references can also be grouped to a job, adding job descriptions etc. This makes handling and pre-configuration of the FLUO ADVANCED for the next printing job fast and straight forward.

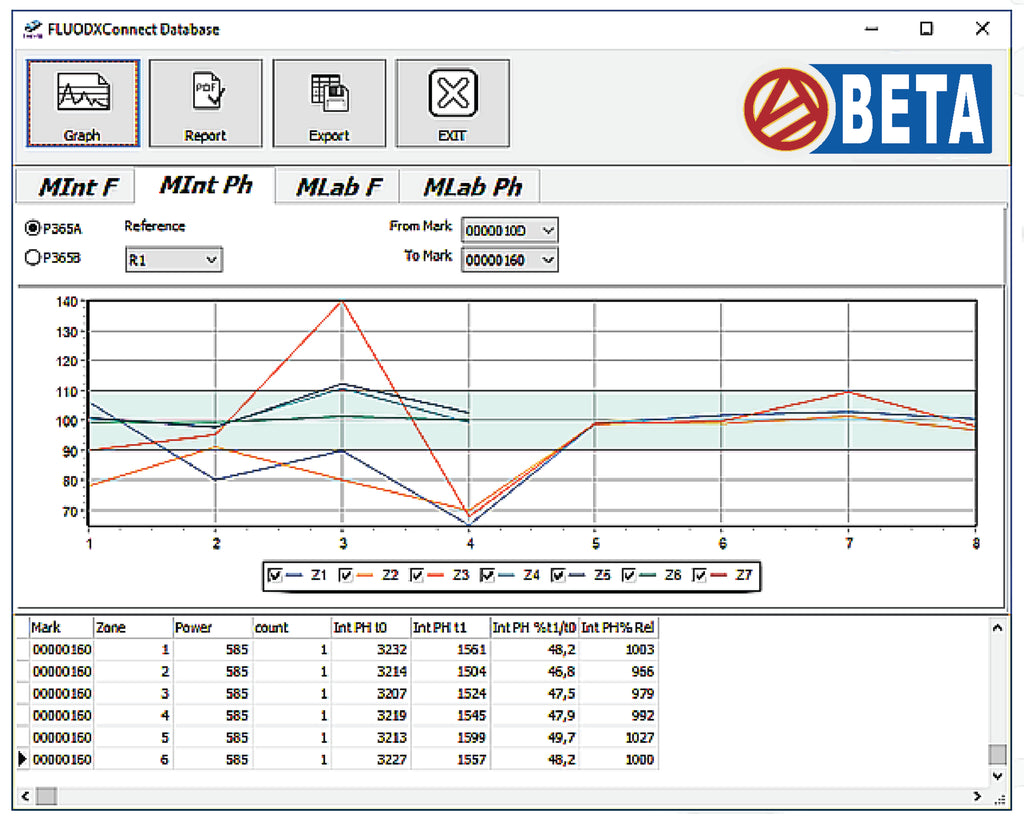

3. Any measurement data uploaded to the computer is automatically added to the measurement database. There are various filter and analysis functions available to analyze the quality of a job. Reports can be created based on analysis results.

4. The FLUODX Connect PRO Software can be protected by a user login. Multiple users can be created and any task performed by a user will be written to a user activity log book. Traceability of device configuration, reference and tolerance modification etc. is given.

FLUODX Connect Software PRO

|

Feature |

Benefit |

|

Works with FLUO ADVANCED, a compact, handheld instrument suitable for production and lab environments |

Save money, use one device in two settings with the same Windows software |

|

Extensive real-time measurement data storage |

No need to be tethered to a computer to capture data |

|

USB connection uploads data and configuration to device |

Easy editing on the PC rather than on device screen |

|

IRDA (wireless infrared) link for extended data download to PC |

No need to be tethered to a computer to capture data |

|

Relational database incorporates jobs, colors, and customers |

Facilitates error-free configuration of the device for the production floor |

|

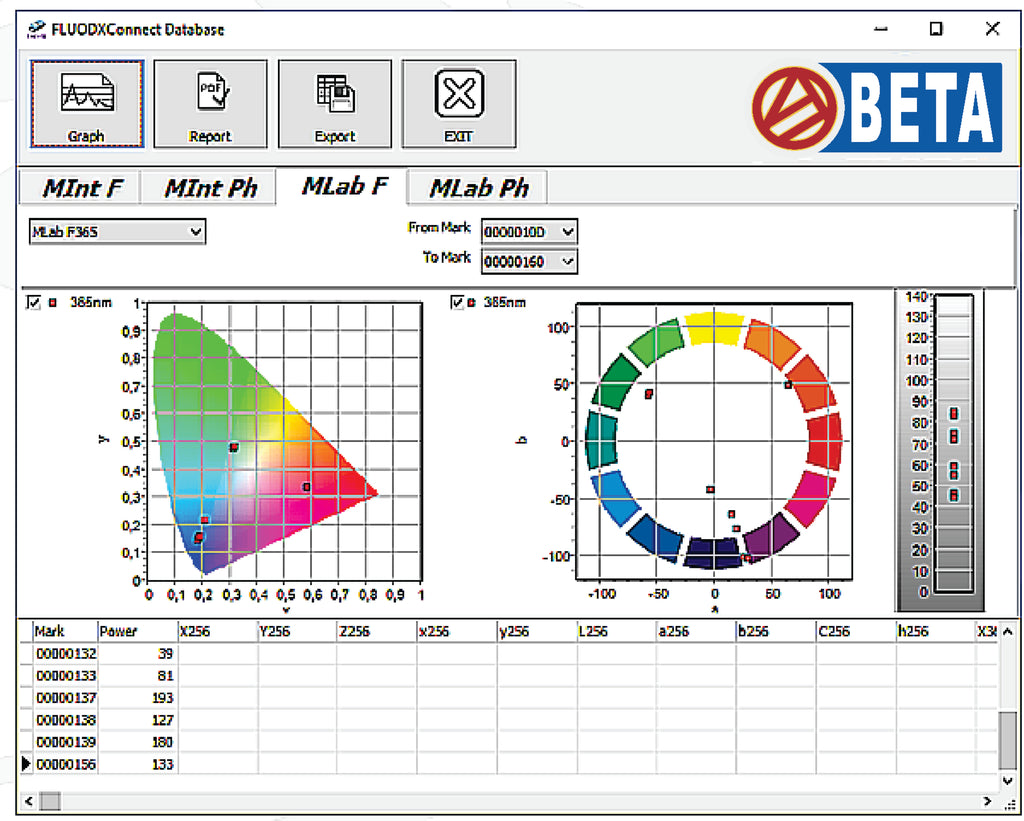

On-screen representation of visual color data |

Helps operators understand color data and nomenclature |

|

Graphical presentation and analysis of production and color data |

No need to export data for graphing and analysis |

|

Full data traceability from print sample to published report |

Compliance with international GMP (Good Manufacturing Practice) and traceability guidelines |

|

Multi-level password protection of device and software configuration |

Prevents unintended or deliberate change to operating parameters, assures data reliability |

|

Works with Windows 7, 8, 10, 32- and 64-bit |

Useable on readily available PC hardware |

|

Real-time screen capture from device |

Simplifies training and documentation |

|

Multi-language user interface |

Comfortable user experience encourages adoption |

|

Clear and logical description of advanced phosphorescence properties and measurement |

Allows machine operators to easily do sophisticated data collection |

|

Extensive Device Configuration options |

Display only the most needed options to simplify the operator’s task |

|

Automatic FLUO ADVANCED hardware identification |

Insures the proper instrument is used to collect data and protect data traceability |

|

Configurable tolerance settings |

Reduces the operator’s need to interpret numerical data, needs only watch the PASS/FAIL indicator |

|

Secure Image Creation function |

Facilitates creation and detailed control of high-security invisible ink images for authentication |

|

Measurement Database holds unlimited data with wide display and analysis option |

QA team can easily create tables and graphs of relevant data for management |

Share This