BetaFlex Pro FlexoEyePlus Database Software with WorkFlow Automation

by Beta IndustriesBetaFlex Pro FlexoEyePlus Database Software

STREAMLINED AUTOMATIC DATA COLLECTOR & REPORT GENERATOR FOR THE BETAFLEX PRO (1&2)

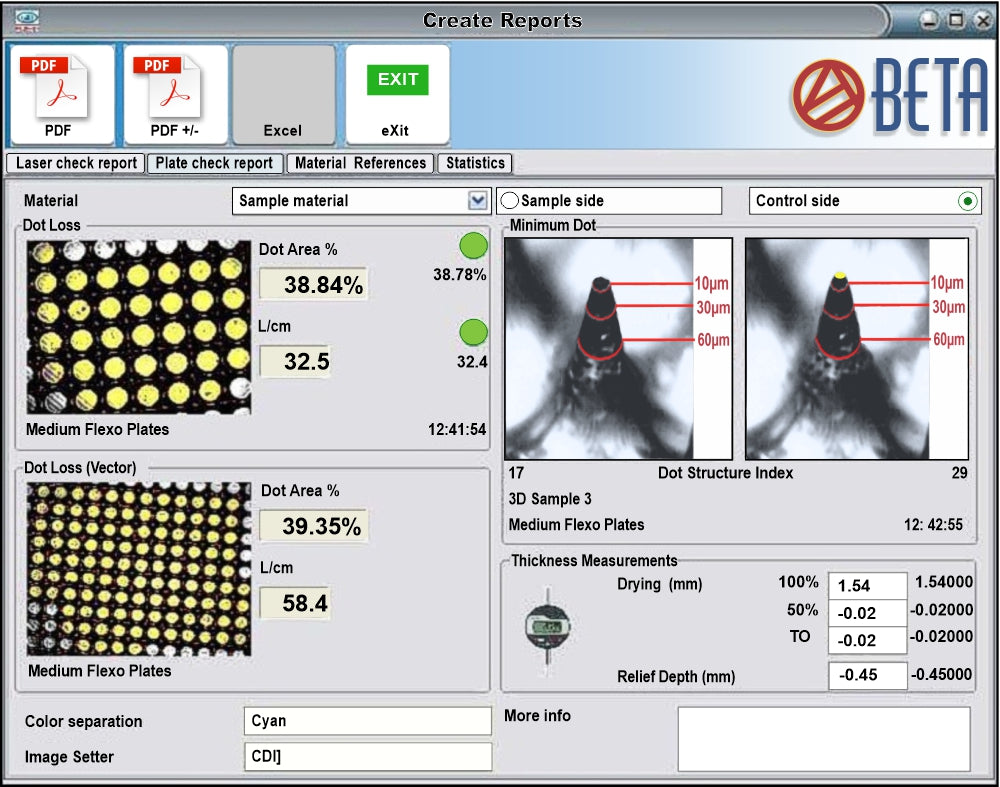

FlexoEyePlus, the optional software data collector & report generator for use with the BetaFlex Pro guides the operator to collect just the plate data needed in a high-volume production environment.

Perfect to exactly document exactly all plate parameters and plate making parameters for gauge & relief (see FlexiGage Micrometer below), for plates made or received for customer's verification, ISO compliance, or internal documentation. Laser Check report, Plate Check report, Material Reference, Statistics, & more, see below

The optional FlexiGage Micrometer measures plate thickness and relief and writes the data directly to the FLEYE+ reports for production control and ISO compliance.

View Technical Document Instruction Manual

FlexoEyePlus simplifies data collection for high-end production. Tightly integrated into the standard software application, it introduces convenient PASS/FAIL icons to evaluate minimum and midtone dot, stain density, cutback curve, plate relief, and more while displaying the data on a concise display and plotting the day's production on a convenient graph. FlexoEyePlus works seamlessly with the optional FlexiGage Digital Micrometer and is a required part of the software suite. Plate gauging data is automatically written into the same report as 2D halftone data and 3D dot structure data.The reporting suite consists of four highly detailed and illustrated reports;

-

Laser Check report – verifies Laser Power, Focus, Linearity, and Minimum Dot formation

-

Plate Check report – ties Plate Material, Job ID, Min Dot, Process and Workflow Curves together

-

Material Reference – allows creation of a Plate material file used as input to Laser and Plate reports

-

Statistics – creates plots of Laser and Plate report data across user-selected materials and dates

The Production Log Report captures user-defined halftone and micrometer data and generates a highly concise one-line report in real-time for each plate. Measurements are automatically compared to targets and tolerances, out–of-spec data is highlighted on the spreadsheet-like report.

xxxx

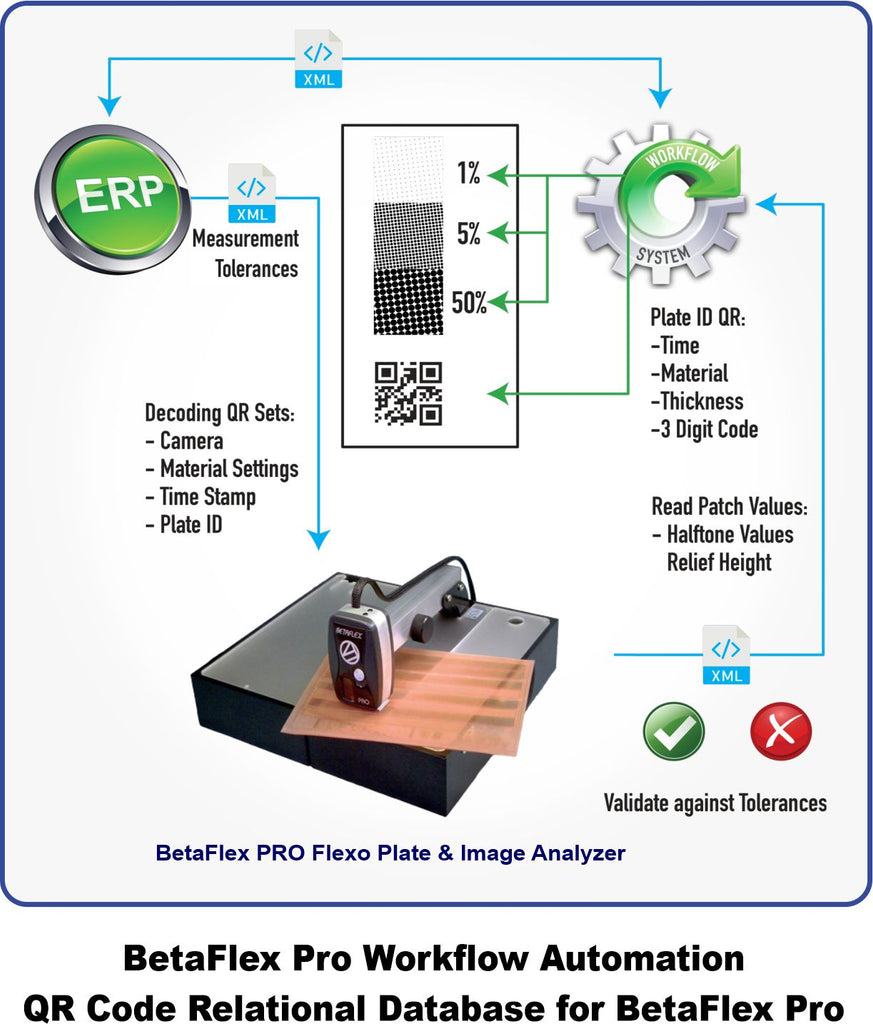

User-defined target values and tolerances can be entered by the QC department to control the PASS/FAIL signals to the production staff. Report generation is automatic and Excel output is created directly in the Statistics section. Reports can be printed with target values and tolerances for internal use or with production data only for sales and marketing purposes. Included with FlexoEyePlus is the NEW BetaFlex Pro Workflow Automation / QR Code Relational Database for the BetaFlex Pro software utilizes a micro QR Code and full relational database to track the photopolymer sheet through imaging, processing, and final QC check Is included with your purchase of FlexoEyePlus Software.

Working in conjunction with the ESKO Automation Engine, the QR code is automatically generated and imaged on the mask. Face and back exposure settings come directly from the Automation Engine. Plate type definitions are contained in the QR Code used to set the plate processor parameters. This eliminates the possibility of operator error when keying in the exposure and processing settings for the plate.

The Micro QR Code on the processed plate is automatically recognized by the new BetaFlex PRO software, setting the measurement parameters, recording the measured results of dot area, dot structure, plate thickness, and relief. Errors in configuration of the BetaFlex PRO due to operator error are now eliminated.

A report is generated and written to the database, linking the plate measurements to the customer and the job.

Options & Accessories

BETAFLEX PRO WORKFLOW AUTOMATION

FlexoEyePlus Software with WorkFlow Automation introduces a completely new method to organize and qualify flexo plate production using the latest hardware and software tools.

-

QR Codes are generated by the user's WorkFlow System, typically the ESKO Automation Engine

-

Micro QR Codes are interpreted and created directly within the BetaFlex Pro application software.

-

XML messaging is used to communicate plate targets and tolerances, plate ID, and instrument settings

-

Hot Folders are maintained for Input and Output of XML Data, Reports, and References.

WorkFlow Automation brochure

WorkFlow Automation PowerPoint pdf

Share This