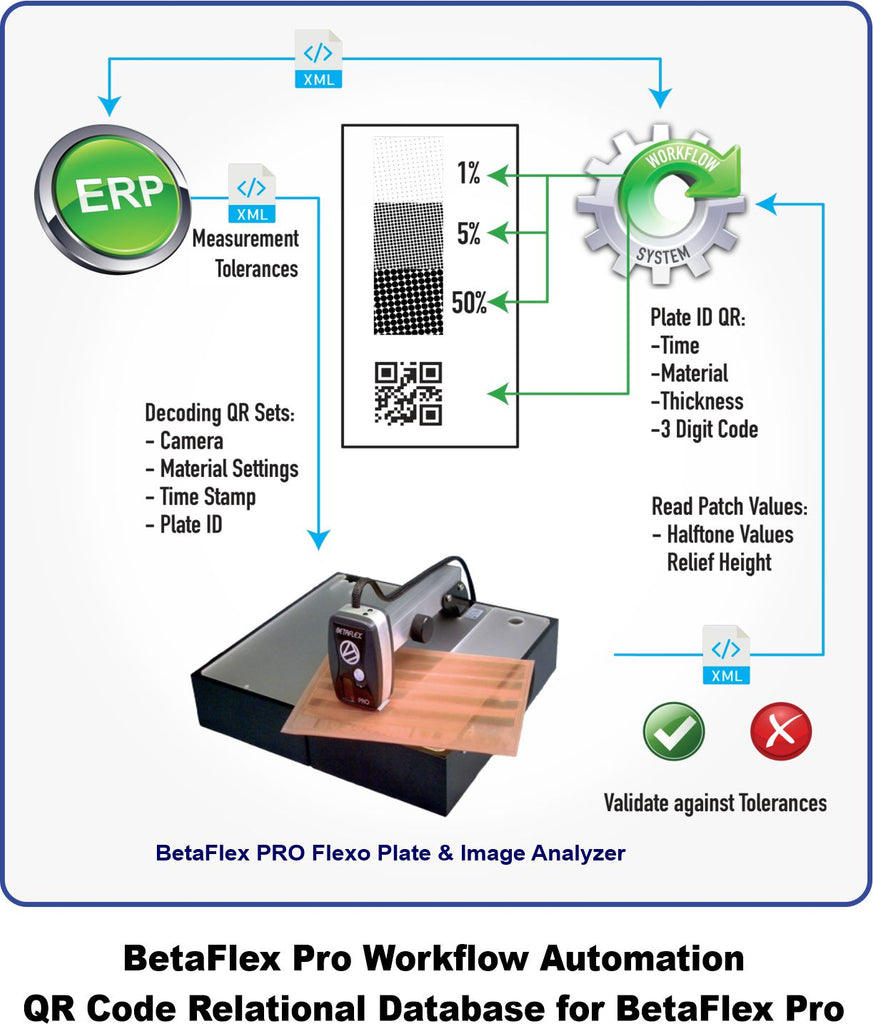

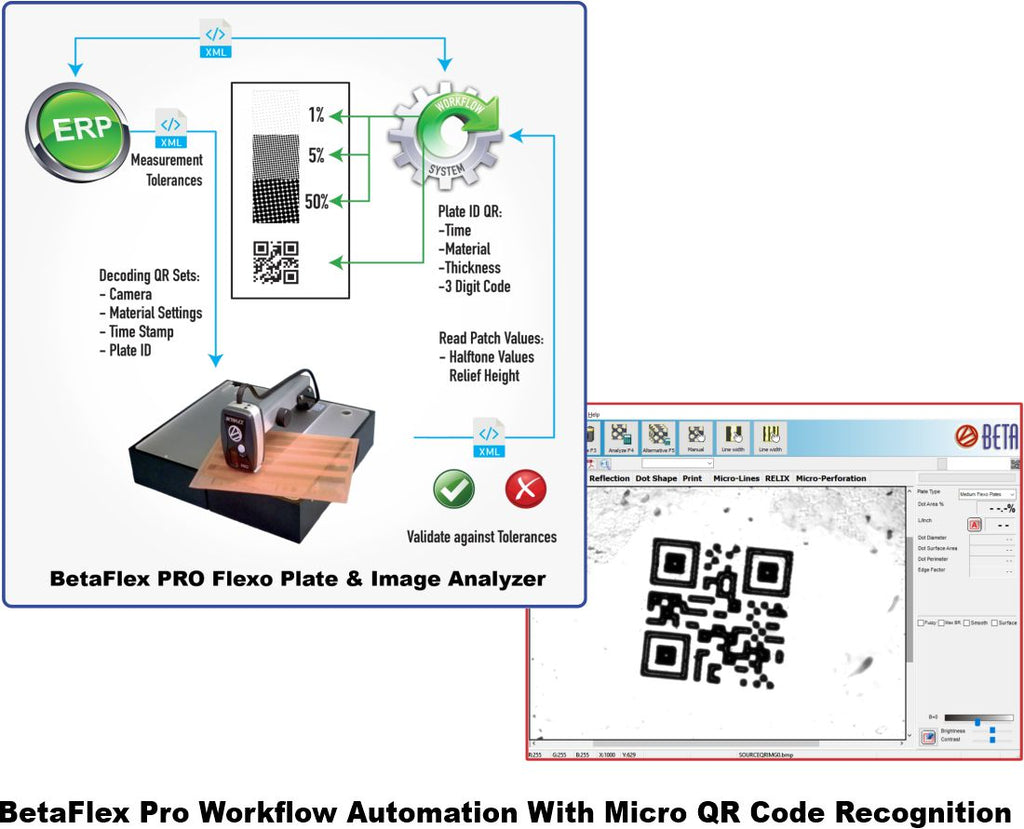

BetaFlex Pro Workflow Automation / QR Code Relational Database for BetaFlex Pro1 & BetaFlex Pro2

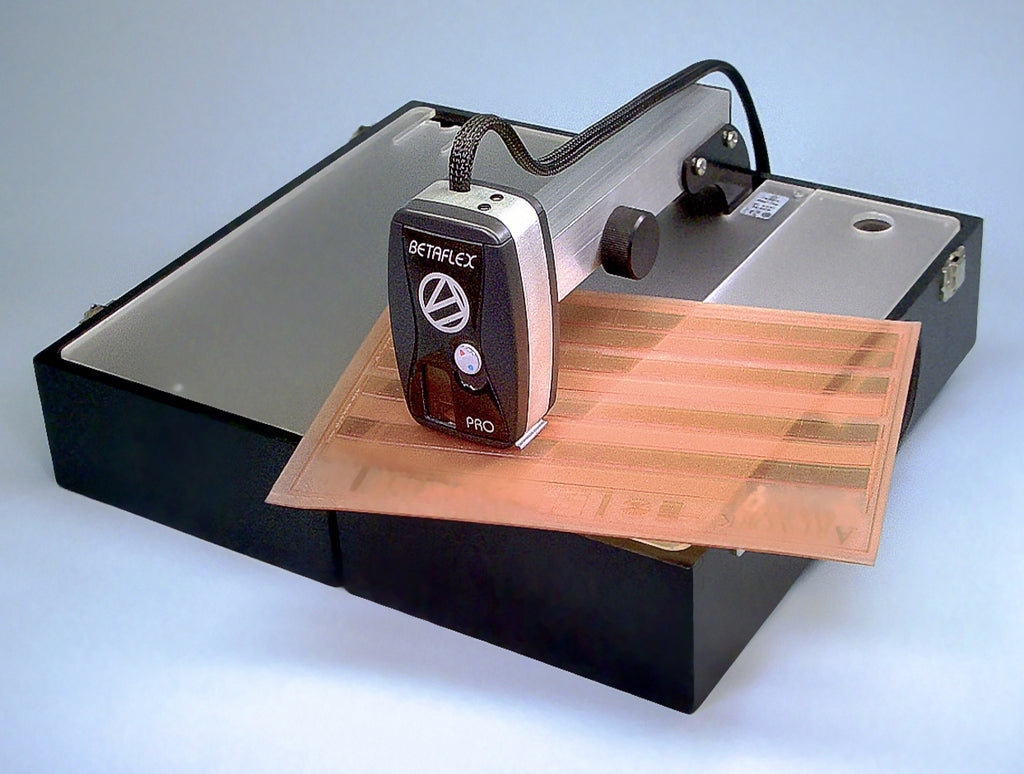

by Beta Screen CorporationYour high volume, multi-plant production will save time, money and materials by automating your workflow with BetaFlex Pro's money saving upgrade to your BetaFlex Pro.

Workflow Automation (part of the FlexoEyePlus Software suite) streamlines and systematizes plate production:

- Identification

- Analysis

- System setup

- Reporting of all plate production parameters

BETAFLEX PRO WORKFLOW AUTOMATION BROCHURE

BETAFLEX PRO WORKFLOW AUTOMATION POWER POINT (PDF)

ddddd

To help ELIMINATE ERRORS and maintain an active relational database of your workflow and production parameters.

- Operator error is eliminated with the automated BetaFlex Pro parameter selection

-

Customized plate types are easily created, verified, and stored in the relational database, as well as transmitted to remote production facilities.

-

Plate identification is written to a Micro QR Code and decoded by the BetaFlex Pro Workflow Automation software.

The system uses:

- QR and Micro QR Codes

- XML messaging

- Your ERP System

- The ESKO Automation Engine

WORKFLOW AUTOMATION uses a micro QR Code and relational database to track the photopolymer sheet through imaging, processing, and final QC check.

REQUIREMENTS:

- Available with the purchase of FlexoEyePlus Software for the BetaFlex Pro.

- The most current version of the BetaFlex Pro Software, Version 6, is required.

How it Works:

Working in conjunction with the ESKO Automation Engine, the QR code is automatically generated and imaged on the mask. Face and back exposure settings come directly from the Automation Engine. Plate type definitions are contained in the QR Code used to set the plate processor parameters. This eliminates the possibility of operator error when keying in the exposure and processing settings for the plate.

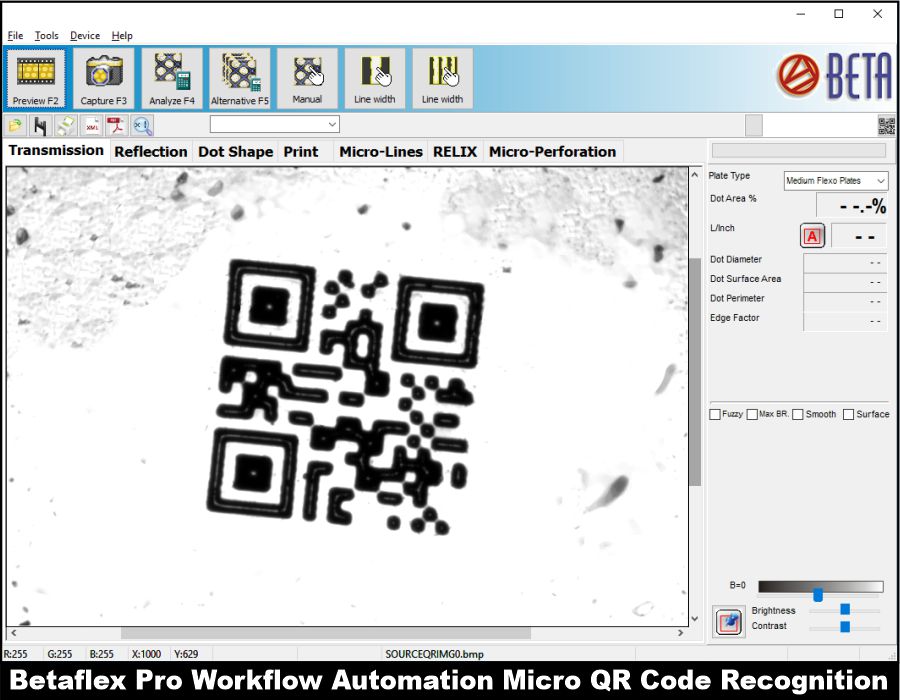

The Micro QR Code on the processed plate is automatically recognized by the new BetaFlex PRO software, setting the measurement parameters, recording the measured results of dot area, dot structure, plate thickness, and relief. Errors in configuration of the BetaFlex PRO due to operator error are now eliminated.

A report is generated and written to the database, linking the plate measurements to the customer and the job.

BETAFLEX PRO WORKFLOW AUTOMATION

FlexoEyePlus Software with WorkFlow Automation introduces a completely new method to organize and qualify flexo plate production using the latest hardware and software tools.

-

QR Codes are generated by the user's WorkFlow System, typically the ESKO Automation Engine

-

Micro QR Codes are interpreted and created directly within the BetaFlex Pro application software.

-

XML messaging is used to communicate plate targets and tolerances, plate ID, and instrument settings

-

Hot Folders are maintained for Input and Output of XML Data, Reports, and References

What is Required:

- BetaFlex Pro Workflow Automation is part of the new FlexoEyePlus software package

- Will require the current BetaFlex Pro software version, BetaFlex Pro Software Version 6 or an upgrade to your current software version.

All of this leads to better, more consistent production, reduced scrap, and more profitable operations plus the consistent and free, live "hands-on" customer technical support that you can always expect and appreciate from Beta Industries.

Share This