BETAFOLD FOLDING CARTON CREASE & FOLD ANALYZERS - BASIC & ADVANCED MODELS (2)

by Beta IndustriesBetaFold Crease & Fold Analyzers

Your BASIC BetaFold Crease & Fold Analyzer can be upgraded to the ADVANCED version with an upgrade code that will unlock the additional features in the software, there is no need to upgrade the software.

The ADVANCED software option adds extensive customization options to the dieline diagram, reporting, and data collection functions.

Open Brochure (see page 2)

Open Brochure (Spanish)

Power Point of BetaFold (PDF Format)

Features Comparison List for all versions and options

Contact Us to be Sent the Demonstration Software

Generic box diagrams are replaced with the actual die diagram, added in the following formats, JPG, BMP, PNG, PDF, greatly improving the production workers understanding of the areas to be tested, etc.

Networked data collection is also implemented, allowing data to be checked across different production locations.

OTHER OPTIONS & ACCESSORIES

BetaFold Power Crease Option

BetaFold Power Box Option

BetaFold, E-Guide 2: Motorized Scanner Encoder

Additional crease profile calculations are also available with this function module. The function can be accessed only if the Power Crease Option option is enabled. Insert the POWER CREASE code by selecting the Power Crease License Item from the Help Menu.

The Power Crease function offers additional job statistics for crease and embossing measurements for The BetaFold Crease & Fold Analyzer.

Power Crease Option offers additional job statistics for crease and embossing measurements for The BetaFold Crease & Fold Analyzer.

Additional crease profile calculations are also available with this function module. The function can be accessed only if the POWER CREASE option is enabled. Insert the POWER CREASE code by selecting the Power Crease License Item from the Help Menu.

Power Box Option control the angles and scoring process, the Power Box function and hardware offers additional job statistics for finished boxes.

E-Guide Pro2 Motorized Scanner Encoder is an optional mechanical tool that guides you while pulling the Betafold over the embossed area. This leads to a repeatable, fast and accurate control of your embossed area. The function can be accessed only if the E-GUIDE option is enabled. Insert the E-GUIDE code by selecting the E-GUIDE License Item from the Help Menu.

Analyze embossing depth, scan a 9x70mm large area, automatically calculates the embossing depth in microns.

Until now, the largest sector of the packaging industry has operated without the benefit of process control instrumentation. Complex creasing, die cutting, and embossing operations were run "by the seat of the pants".

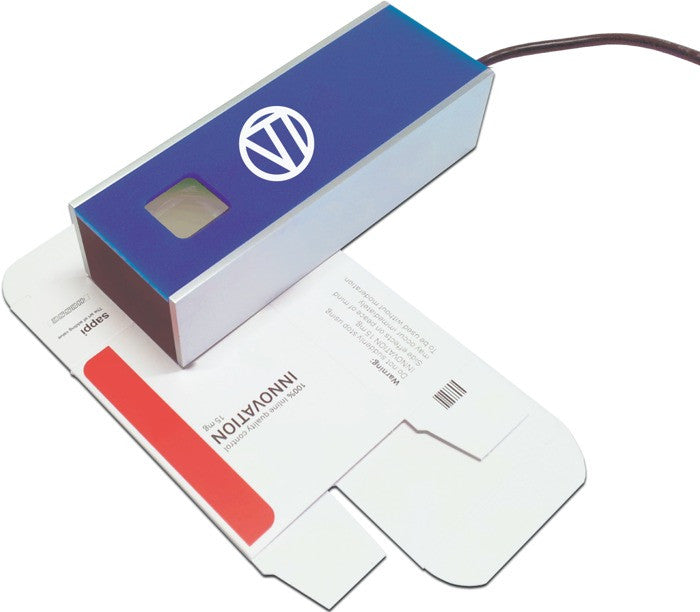

The BetaFold Crease & Fold Analyzer is a high resolution, portable, non-contact, hand-held sensor that captures an image of the die cut and creased flat sample prior to folding and glueing.

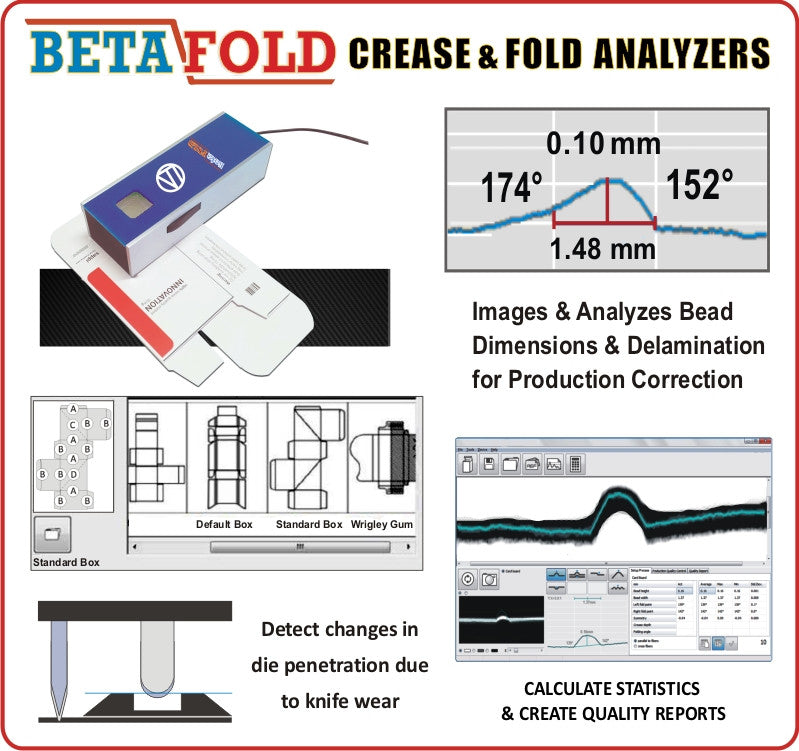

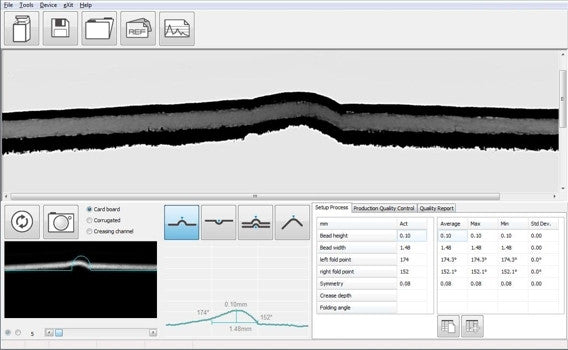

Fully automatic analysis of crease height, width, angles, and symmetry is done on the PC. The data is automatically saved to a database.

The device is uniquely suited to both in-depth analysis of the many variables that affect the finished product as well as quick grab-samples by low-skill production workers.

Data and images are easily captured and printed with the integral report generator and statistical analyzer.

The system maintains a database of job setup parameters and production samples.

-

Measure crease and channel width, depth, angles, and symmetry

-

Save images and data with a single click

-

Display, save, and print data for complete control

When used for package design, material and process evaluation, or machine make-ready, detailed information is available to the professional.

In the high-volume production environment, the machine operator needs only one click on each critical detail to automatically capture production data in the database. Statistics are automatically calculated and formatted reports are generated for documentation and process control.

Using only passive optical technology, the BetaFold is immune to the problems associated with other systems.

- Depth micrometers are simple and inexpensive, but poorly suited to measuring potentially soft, hard-to-see features. Operator technique is important, leading to bad data in untrained hands. BetaFold requires no operator expertise and guides the user to measure the required features.

- A profilometer uses a mechanical stylus to scan the surface of the sample. The stylus is delicate, exposed to external forces, and easily damaged. BetaFold avoids the problems of the delicate stylus and the moving parts to scan across the sample.

- Focus scanning systems create a depth coded image. The systems are expensive and contain delicate moving parts. The scanning process is inherently slow and computationally intensive. The software is complicated for the operator to understand. BetaFold image capture is instantaneous with measurement results generated immediately on screen.

- Laser interferometers are extremely expensive, delicate, and complicated. The extremely high resolution that they are capable of, and the associated cost, is wasted on the creasing and embossing process. BetaFold provides appropriate technology without excessive expense or complication.

Folding cartons are made of paperboard, and the multi-layer construction contributes bending stiffness to the board. In order to make a high quality fold with good appearance and structural integrity, the bending stiffness has to be reduced by the creasing matrix. This localized weakening of the board in a well-defined pattern act as hinges during the subsequent box forming process.

Uncontrolled variations in the creasing process can create defects that affect the appearance and function of the finished carton. Proper setup is critical to assure a consistent product. BetaFold is a new hardware and software system to measure and document the dimensions, angles, and symmetry of the crease and the bead. This aids in proper setup and offers a method of process control to the production run.

CREASING breaks fiber bonds between plies, allowing controlled delamination and creating a hinge

-

MEASURE Bead crease, folding angle

-

VERIFY Bead height, width, symmetry, fold points

-

DOCUMENT crease images and data, generate reports and statistics

-

IMAGE and ANALYZE bead dimensions

-

CREATE Production reports with images and statistics

-

DETECT changes in die penetration due to knife wear

CONTROL

-

Faster creasing makeready

-

Minimize cracks and splitting

-

Reduce running defects and waste

-

Improve package performance and profits

ANALYSIS

-

Measure sample vs production crease parameters

-

Detect ink and coating effects on folds

-

Verify proper drying and environmental conditions

-

Track die performance vs time and operator

Contact your local dealer or Beta Industries for pricing, delivery, and training information.

The BetaFold Crease & Fold Analyzer is also sold under the CREASY brand in Europe and Asia.

About Beta's 10-Day Free Trial for this product, Click Here.

#Creasy, #BetaFoldCreaseFoldAnalyzer, #AnalysisCorrectionofFoldsCreases, #FoldingCartonIndustryHighEndProductPerfumeBox, ConfectionsBoxManufacture, #CosmeticsBoxProductionCreaseFold, #CigaretteBoxCreaseFoldAnalysis, #CartonCreaseAnalysis, #CartonFoldAnalysis, #HighEndFoldingCartonProducts

Share This