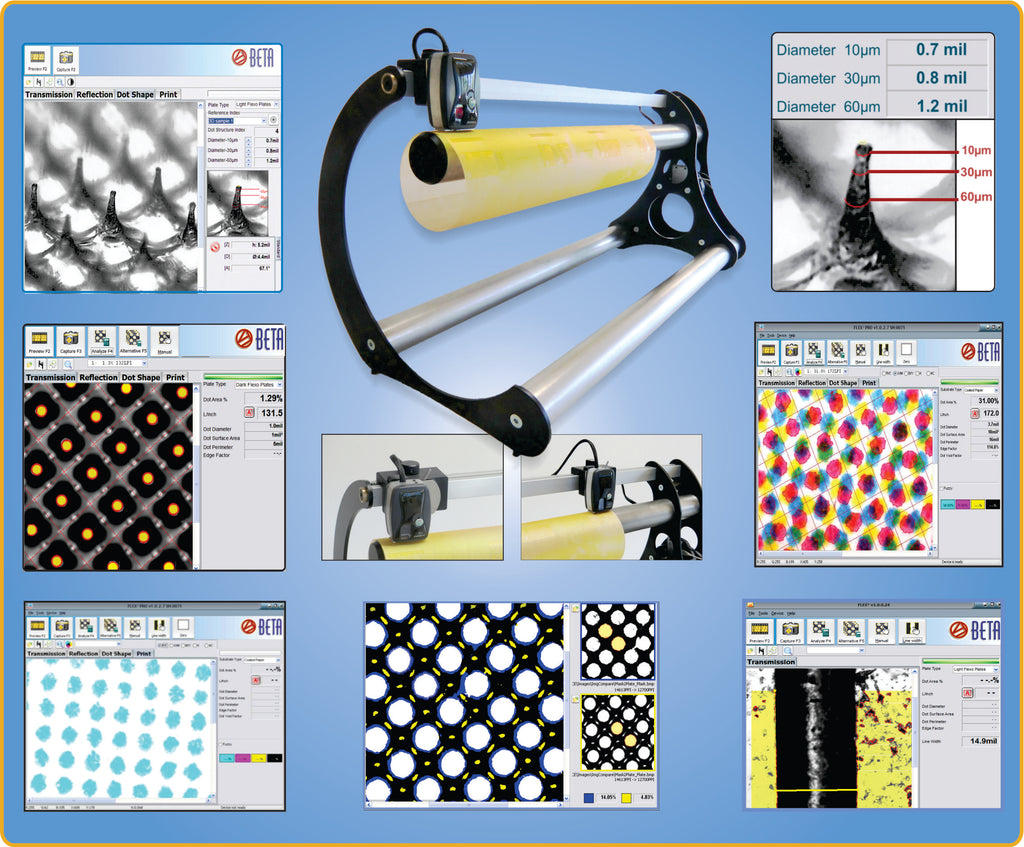

BETAFLEX PRO - FLEXO SLEEVE MEASURING SYSTEM

by Beta IndustriesThe Benefits of BetaFlex Pro Technology for Your In-The-Round Sleeve Production

-

Supports sleeves up to 80 inches / 203.2 cm wide, 15.7 inches / 39.8 cm in diameter

-

Measure flexo plates and digital masks in conventional 2D mode

-

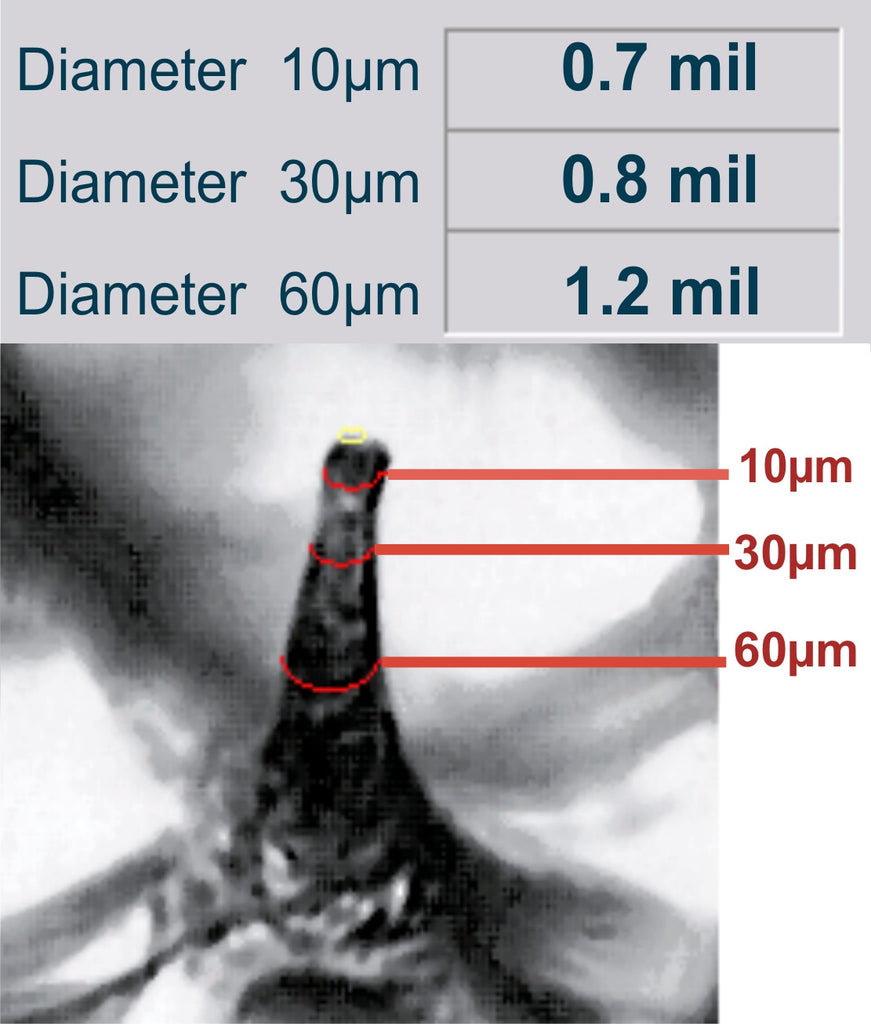

Dot Structure Analysis in 3D mode reveals dot height, slope, and more

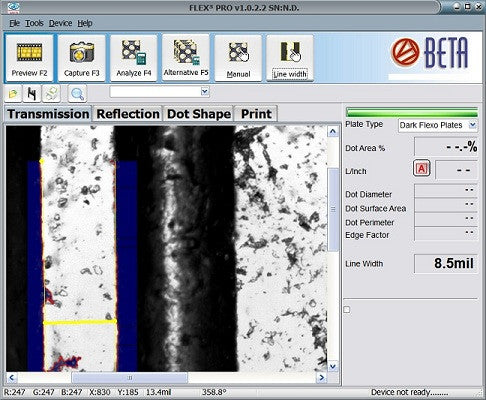

The new Betaflex Pro system operates at the highest resolution to provide the most accurate and consistent measurements. HD Flexo, stochastic screening, and all the most sophisticated prepress techniques can be measured and controlled with ease and accuracy.

Contact us to purchase this product.

Revolutionary 3D imaging and DOT STRUCTURE Mode add topographical visualization to the conventional dot area halftone measurements. Dot height, diameter, slope and more are visualized and automatically measured at 22,000 PPI. Surface enhancement techniques are easily seen and quantified.

Operating in TRANSMISSION mode at 14,000 PPI, it quickly and accurately measures all types of transparent flexo sleeves.

The optional Flexigage Micrometer allows precise measurement of overall sleeve thickness and plate relief. Interchangeably mounted on the same support as the imaging head, the electronic micrometer features one micron resolution, remote spindle lift, and automatic data collection. When used in conjunction with the FlexoEyePlus data collection / report generator software, plate gauging data is automatically written into the same report as 2D halftone data and 3D dot structure data.

All of this is combined with the high precision, ease of use, and Beta product support that has made Betaflex the standard of the industry for Flexo Quality Control.

Two versions are available;

1) If you already own a BetaFlex Pro then simply add the adaptor system with your existing BetaFlex Pro sensor / measuring head ($8,400)

2) A complete BetaFlex Pro Sleeve Adaptor System including sensor / measuring head, ($16,300). Includes all necessary hardware software to be up and running from the start.

Contact us for more information

BetaFlex Pro Options & Accessories

Betaflex Pro Testimonials

The Betaflex Pro helps my team produce better work through live images and measurement data.

Its easy to use/learn; after a few uses operators have it down. As a manager this device has helped us 'cut through the bias' during plate & print troubleshooting and kept the focus on the problem/solution. You cannot put a price on that; after a few print/plate troubleshooting sessions it paid for itself.

I have only contacted the Betaflex support team once or twice and they had an answer for me in less than 24hrs.

I would recommend the Beta Pro to anyone producing flexo or letterpress plates as well as film negatives. It also works well as a print analyzer.

When it comes to plates seeing is believing and measurement is king; BetaFlex Pro does both. We are very satisfied with the product.

Steven Rice

Dart Container

------------------------------------------------------------------------------

As a QA tool it does help us “produce better work” by allowing our team to peer into our platemaking process to ensure that the final product is within the established ranges for each attribute that we measure.

The customized settings for plate specific tolerances have been quite helpful. The foot pedal for the controls also means more of a hands free operation that some operators find helpful.

As plate technologies have evolved and process controls have become tighter, it has become very important to have a dependable measurement tool that allows you to measure and understand what is imaged on the mask and what is formed on the finished plate.

We have established a good relationship with Beta. They have been willing to understand what we were trying to accomplish and have done a good job supporting our efforts via email, phone calls, and screen sharing support.

If someone was looking for a tool to help them better understand their platemaking process and is willing to invest the time to setup the proper procedures, then we would certainly recommend the BetaFlex Pro.

Tyler S. Mills

Special Projects Manager | Cyber Graphics

------------------------------------------------------------------------------

We have been using the BetaFlex Pro for approximately 3 years.

We find it very helpful to assess the quality of our printed product and to refer to it to analyze and determine if adjustments are necessary at press side, or in pre-press.

We also use it to review HD dots on our plates. There have been numerous occasions where the Betaflex PRO has saved us money at press side.

I enjoy using the BetaFlex Pro and have found it to be a very valuable tool.

Dina Russo

Yerecic Label

Pre-Press Manager

------------------------------------------------------------------------------

I have discovered a new solution for reading white ink mottle on PRINTED FOIL!

This stunned the printer in 15 minutes as they have been searching for a way to do this for a long time. Ironically while I was there they were conducting white ink trials on foil and using only using visual pass/fail methods.

I did this on my computer with my BetaFlex Pro in front of them. I could not have done any of this without the BetaFlex Pro.

David A Recchia | Application Development Sr.

Printing Process Specialist

Macdermid Printing

Share This