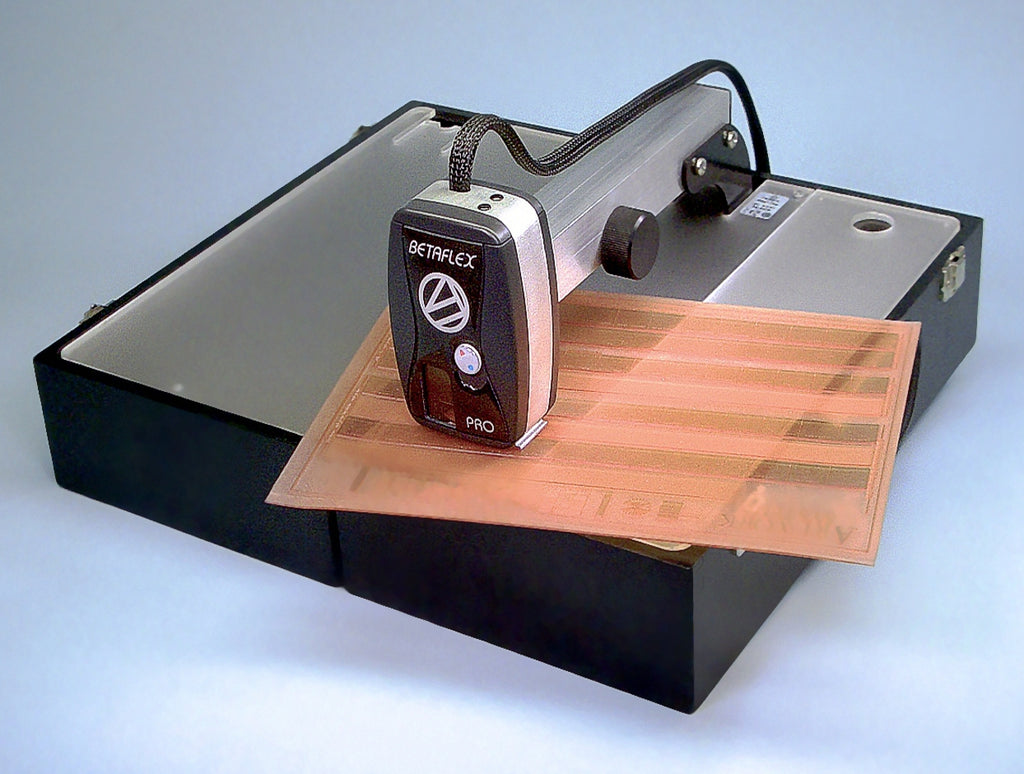

BetaFlex Pro1 Software Version 6 Upgrade, New Features & Windows 11

by Beta Screen CorporationBetaFlex Pro1 Version 6 Software Upgrade & Windows 11 Compatibility

Trouble With Your older BetaFlex Pro1 Software? If you have the older Version 3 and 4 software and have been waiting to upgrade to Version 6.

Version 5 software is Windows 11 compatible but the added benefits of Version 6 are worth the upgrade!

Upgrade to the Latest Version 6 Software & Guarantee Windows 11 Compatibility & Enjoy the Benefits of New & Improved Features!

-

Micro cell screen measuring

-

Measuring metal backed plates

-

Improved measurement of white ink film mottle and more

Details of Version 6 Software (pdf)

The Newest Update to the BetaFlex Pro1 Software Offers Many New Features for BetaFlex Pro1 users with software prior to version 5

-

Upgrade your existing BetaFlex Pro(1) to measure the latest surface screening technologies

-

View 3D images with increased high resolution (HDRC)

-

Improvements for measuring white ink mottle on transparent film

-

Improvements for measuring metal backed plates

Version 6 brings numerous new features, improvements, and usability enhancements to the world’s most popular flexo analyzer.

Click Here to download the Version 6 Software Upgrade if you have already purchased a license code for the BetaFlex Pro1 Version 6 Upgrade

Be sure to include your Betaflex Pro1 Serial Number in the Order Notes section when placing an order for this upgrade.

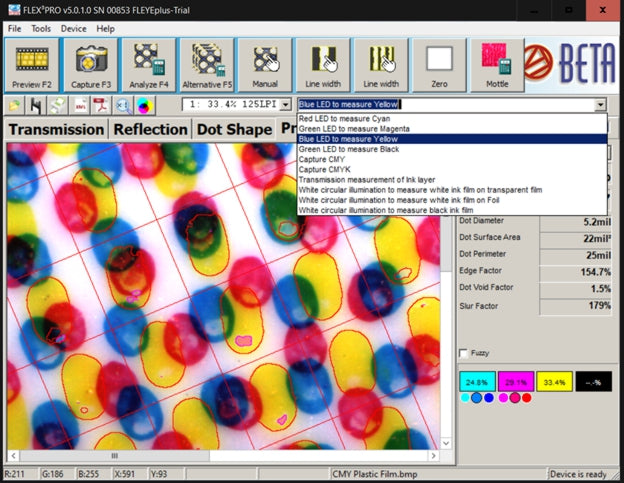

Surface Screening

-

Measure the true ink-receptive area of plates with surface screening

-

Create Custom Plate Types specific to Transmission, Reflection, and 3D Imaging modes

-

Measure print mottle of solids on clear film, white film, aluminized film, foil, and paper

-

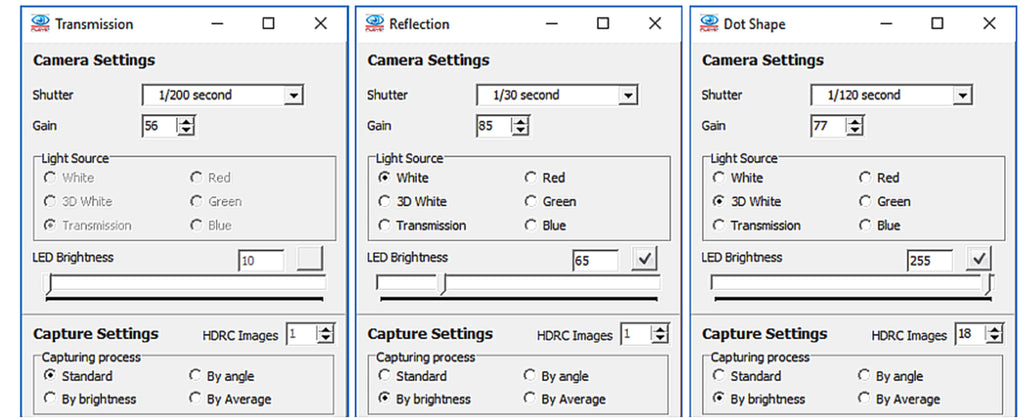

HDRC (High Dynamic Range Capture) imaging now available in all imaging modes

-

Create Custom Substrate Types for improved Print analysis

-

Dual Monitor support

Custom Plate Types & Substrate Types

There are various parameters that can be used to define a special plate type. Plate measurement now has the ability to test the best camera settings, the optimum capture and image filter settings, and the analysis parameters. Earlier Software versions required settings to be changed in various locations of the Software, and some settings couldn't be modified at all. Version v5.x now makes the definition of customized plates significantly easier and more flexible.

Improved User Interface

High Dynamic Range Capture (HDRC)

a. Measure all variants of the latest surface screening technologies. These high resolution patterns are applied to solid and halftone dots alike, improving ink transfer, reducing dot gain, and creating better solids with less mottle.

- This feature is useful to show the benefits of advanced surface screening technologies from ESKO, Dupont, Kodak, Macdermid, and others, and is similar to imaging with a portable, laboratory grade instrument.

b. HDRC (High Dynamic Range Capture) in 3D Dot Shape Mode. This function captures multiple exposures of the same feature and automatically selects images that carry the greatest detail. A compound image is then created and displayed on screen.

- This feature can be useful for technical experts to better SEE how adjustments to the various process parameters affect the finished product.

Contact us to obtain a software license for your BetaFlex Pro(1).

Other Version 6 features;

- A relational database used by all aspects of the base software and the optional FlexoEyePlus Software data collection and report-writing feature

- Backward compatibility with the flat files used in Ver. 5 and earlier

- Update function to migrate the flat files to the relational database

- XML import and export of all data and settings to allow integration with ERP and WorkFlow systems

Another important feature in this software release is compatibility with the Betaflex HR High Resolution system for control and diagnosis of advanced cell patterning techniques. One computer can now simultaneously run the BetaFlex Pro(1) for mask, 2D and 3D plate analysis, and print measurement and the Betaflex HR for surface screening control on masks and plates.

Details of Version 6 Software (pdf)

Be sure to include your BetaFlex Pro(1) Serial Number in the Order Notes section when placing an order for this upgrade. When you receive an email with your Ver. 6 License;

-

Download the UPGRADE if you are upgrading an existing installation

-

Download the SETUP if you are creating a new installation or installing on a new computer

Click Here to download the Version 6 Software Upgrade.

Version 6 will be required in order to run the latest version of FlexoEyePlus Software database and report generating software.

FlexoEyePlus Software with WorkFlow Automation introduces a completely new method to organize and qualify flexo plate production using the latest hardware and software tools.

- QR Codes are generated by the user’s WorkFlow System, typically the ESKO Automation Engine

- Micro QR Codes are interpreted and created directly within the BetaFlex Pro(1) application software

- XML messaging is used to communicate plate targets and tolerances, plate ID, and instrument settings

- Hot Folders are maintained for Input and Output of XML Data, Reports, and References

As new plate materials, substrates, and imaging techniques are introduced to the industry, the BetaFlex Pro(1) system accommodates them all with enhanced Customized Plate type and Substrates.

Companies with multiple plate production facilities can now eliminate local variations due to out-of-date specifications and enjoy greater accuracy and repeatability. Targets, tolerances, measurement data, and device settings are all communicated via XML messaging with automatic file updates and verification.

Share This